Transforming public transport worldwide with fast-charging e-buses

Swiss-based, family-owned HESS – with nearly 900 employees, more than 500 of whom are in Switzerland – has made its mark in the bus and e-bus production industry, thanks to its highly customised approach. Today, HESS buses are fully electric and have a life span of at least 20 years. This medium-sized company, together with its international licensees, currently produces around 2,400 buses annually.

Making cities and surroundings more sustainable with fast-charging e-buses

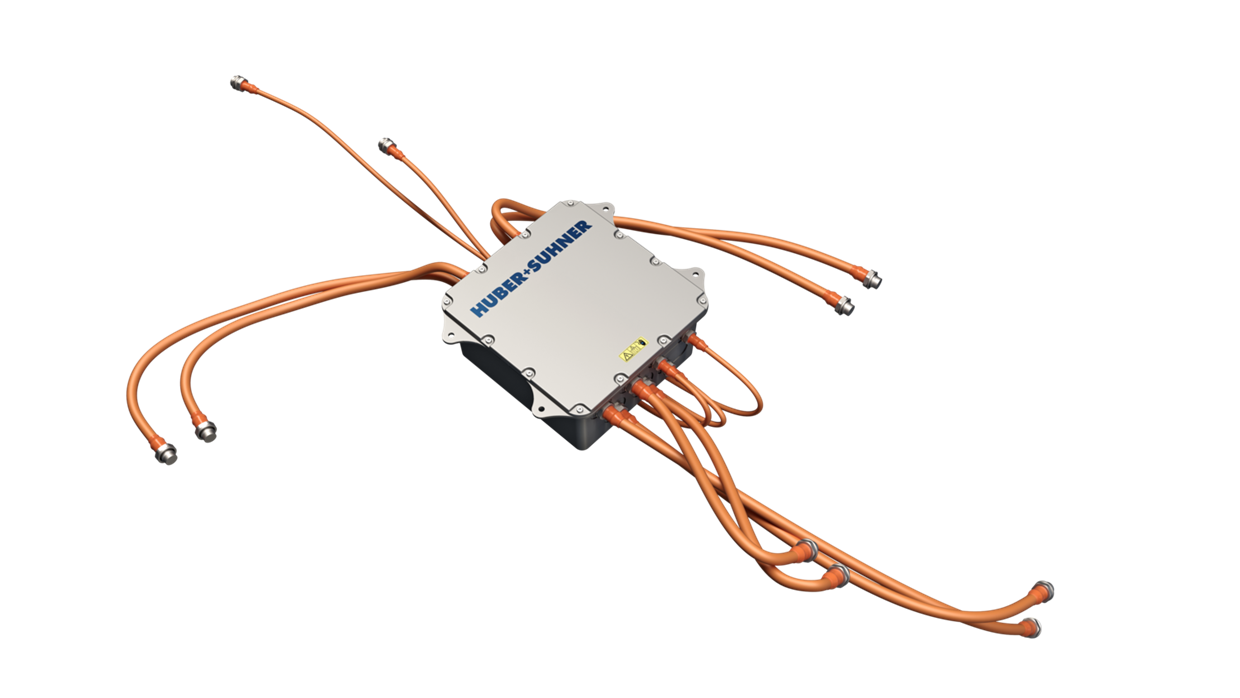

The HESS battery operated traction buses are highly customisable to the available e-charging infrastructure. Both the HESS lighTram® trolleybus generation and fast-charging buses are charged via their roofs – either with a current collector at the overhead line or with a pantograph directed and positioned by laser in only 20 to 30 seconds at bus stops or at the terminal. The vehicles’ innovative energy management allows integral optimisation of all on-board energy consumption. Highly reliable performance as well as a 20-year warranty for their e-buses attract prospects and retain HESS customers which are primarily in Europe (Switzerland, France and Austria). Furthermore, lighTram® e-buses have been delivered to Brisbane, Australia, showing the capacity of the e-buses to operate under various harsh weather conditions such as heat, cold, and humidity. HUBER+SUHNER has been providing its modular High Voltage Distribution Units (mHVDUs) – called contact boxes by HESS – tailored to their needs. mHVDUs support original equipment manufacturers (OEMs) like HESS in bringing new electric vehicles to market fast and in a cost competitive way while ensuring highest level of quality.

Staying at the forefront of innovation

At HESS, prototyping is not possible due to the company’s size. On the other hand, customers have high demands with regards to product development, while HESS must also focus on its own innovation in parallel with customer needs. The regulatory environment concerning functional safety and cybersecurity present additional demands. All these factors played into the valuable collaboration between HESS and HUBER+SUHNER once the prototyping phase for the mHVDU contact box got underway. The success of this process led to the development of crucial e-bus components that provided flexibility in terms of the charging design, whether it involved a plug or a rooftop solution adaptable to higher or lower current. This collaboration is a perfect example of how we help system integrators like HESS achieve next-level process management.

“The quality of our battery charged e-buses, the longevity, low failure rates but also maintenance and flexibility with regards to new product requirements are highly important for our customers next to innovation and our ability to meet specific needs. For our partners, it is key to keep up with latest innovations and thought leadership that we as a market leader push for, but also that we can successfully manage pressure in terms of cost efficiency while still delivering highly customised e-buses.”

Jvan Leider, Sourcing Manager, HESS AG

Continuous innovation and thought leadership in e-bus manufacturing

With its portfolio, HUBER+SUHNER provides HESS to choose the right size and quantity of mHVDU contact boxes, going beyond typical off-the-shelf offerings of one big box that often offers much more than is needed. With the small mHVDU contact boxes from HUBER+SUHNER, HESS saves space and achieves both economic and ecological benefits, as the design and number of contact boxes are tailored to the actual need of a particular e-bus model. Moreover, natural resources used by semiconductor industry are finite and many players take into account the economic and environmental impacts of consuming and transporting these resources. Alongside the mHVDU contact box that can operate several batteries without a multi-connector, the prototype stages of the collaboration have resulted in serial production of four variations adapted to HESS requirements. The project demonstrates the power partnership between two Swiss-based, globally active companies with a shared vision of flexibility, innovation, sustainability, and highest quality standards.

“HUBER+SUHNER offers robust and high-quality products which are appreciated by our customers to produce highly customised, reliable and long-lasting electric vehicles. The varying areas and conditions where electric vehicles are in use expose them to harsh environmental conditions. This implies highest requirements for our mHVDU. With HESS, we have found a Swiss partner that pays just as much attention to innovation, quality and longevity as we do. The very trusting and open communication between HESS and HUBER+SUHNER, even in challenging moments, contributed in large part to the success of this project.”

Amon Mundinger, Regional Sales Manager Automotive, HUBER+SUHNER